Legionella control FAQs

What is Legionnaires’ Disease?

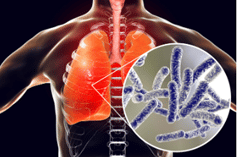

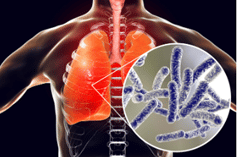

Legionella control FAQs – Legionnaires’ disease is a potentially fatal pneumonia caused by bacteria called Legionella pneumophila. Exposure to the Legionella bacterium can happen when you inhale contaminated mist or breathe in droplets of water contaminated by the bacteria.

There are many ways to prevent legionnaires’ disease, including routine inspection, temperature monitoring, and maintenance of cooling towers, water tanks, and plumbing systems.

Legionella control FAQs

Who can catch Legionnaires’ disease?

Everyone is potentially susceptible to infection, but some people are at a higher risk e.g. those over 45 years of age, smokers and heavy drinkers, those suffering from chronic respiratory or kidney disease, and people whose immune system is impaired. Symptoms of Legionnaires’ disease may include fever, chills, headache, muscle aches, and tiredness.

Everyone is potentially susceptible to infection, but some people are at a higher risk e.g. those over 45 years of age, smokers and heavy drinkers, those suffering from chronic respiratory or kidney disease, and people whose immune system is impaired. Symptoms of Legionnaires’ disease may include fever, chills, headache, muscle aches, and tiredness.

Where is legionella found?

Legionella bacteria (legionella pneumophila) are common in natural water courses such as rivers and ponds. Since legionella is widespread in the environment, they may contaminate and grow in man-made water systems such as cooling towers and hot and cold-water services. Spa baths, Jacuzzi’s and hot tubs also provide a potential breeding ground for legionella bacteria as they provide optimum conditions for the bacteria to grow and multiply to sufficient numbers for a system to be colonised.

Legionella bacteria (legionella pneumophila) are common in natural water courses such as rivers and ponds. Since legionella is widespread in the environment, they may contaminate and grow in man-made water systems such as cooling towers and hot and cold-water services. Spa baths, Jacuzzi’s and hot tubs also provide a potential breeding ground for legionella bacteria as they provide optimum conditions for the bacteria to grow and multiply to sufficient numbers for a system to be colonised.

The bacteria thrives at temperatures between 20 and 45 degrees, particularly if there is a supply of nutrients such as rust, sludge, scale, algae, and other bacteria.

The risk of legionnaires’ disease is increased if water droplets are produced and dispersed in aerosol form for example, in a shower or spa bath.

It is possible to reduce the risk by removing exposure to water droplets and aerosol and by removing the nutrients on which the legionella bacteria feed. This can be done by keeping water systems clean by cleaning and disinfecting cold water storage tanks and showerheads.

How do I the with latest HSE guidance?

The current HSE guidance documents for the legionella control are the L8 Approved Code of Practice and the HSG274 Legionella technical guidance.

The first thing to do is a Legionella Risk Assessment, to consider the risks from legionella that may affect your staff or members of the public, and then take suitable precautions to control and prevent the risk.

Is it a legal requirement to have a legionella risk assessment?

There is a legal duty for employers and landlords to consider the risk legionella bacteria in buildings under your control or management. You must identify and assess the source of risk i.e carry out a legionella risk assessment. Manage the risk. Put in place measures to control or prevent any risks. Keep good records to prove you are taking the appropriate action and to show to external agencies you are following the HSE guidance for legionella control.

What can be used to control legionella bacteria?

Temperature is usually used in hot and cold-water systems, by keeping hot water at above 60 degrees and ensuring it is above 50 degrees at the outlets. Cold water should be kept below 20°c.

There are other methods that can be used if the temperature is not an option, such as copper/silver ionisation and chlorine dioxide. Cooling towers/systems are often treated with biocides. There are other treatment strategies available such as ultraviolet (UV) irradiation.

Do I need to take Legionella samples?

This depends on the risk assessment and control methods being used. In some circumstances it will be required, however, it needs to be done at a UKAS accredited laboratory and will require specialist help. Dantek can provide advice on sample frequency and locations, and what to do if Legionella is detected.

Routine Legionella testing however is not a requirement in domestic hot and cold-water systems. It would only be recommended in hot and cold-water systems due to exceptional circumstances where typical control measures are not working. A full legionella risk assessment would identify the best course of action to reduce the risk.

What will a legionella risk assessment cost?

The cost will depend on what assets are on your site and how many buildings. For large sites or multi-site portfolios a site visit by one of our team is the best way to establish exactly how much a risk assessment will cost. However, we are often able to provide a guide price if you know roughly the size and type of building. For example, how many floors, what it is used for, whether there are any cold-water storage tanks, number of calorifiers and if there are any cooling towers. An asset register of plant and equipment can be very helpful in determining how long the on-site assessment will take and therefore the cost.

The cost will depend on what assets are on your site and how many buildings. For large sites or multi-site portfolios a site visit by one of our team is the best way to establish exactly how much a risk assessment will cost. However, we are often able to provide a guide price if you know roughly the size and type of building. For example, how many floors, what it is used for, whether there are any cold-water storage tanks, number of calorifiers and if there are any cooling towers. An asset register of plant and equipment can be very helpful in determining how long the on-site assessment will take and therefore the cost.

One of our team would be happy to talk through on the phone any requirements and enquiries.

What do Landlords need to do about Legionella control?

The law clearly states if you are a Landlord and rent out your property then you have a duty under Health and Safety Law to consider the risk posed by Legionella bacteria. The ACoP L8 (3rd edition) also states Landlords must assess the risk from exposure to legionella to their tenants.

In most cases the risk assessment is simple and straight forward, however for more complex systems or if the Landlord is not able / competent to carry out the assessment they can use a specialist Water Treatment Company like Dantek, to carry out the legionella risk assessments and advise on any actions required.

A simple risk assessment will identify if a system is considered a low legionella risk and no further actions are required other than to review the assessment regularly in case anything changes which may affect the risk for example the water system in the building changes.

Examples of low risk systems include;

- A small building occupied by people not considered at risk from legionella bacteria.

- Where there is enough usage of water per day to ensure the entire system is changed at least once.

- Mains fed cold water supplies the entire system, so there are no cold-water storage tanks.

- Hot water is fed from combi boilers/ instantaneous heaters or low volume water heater where the hot water is supplied at no less than 50°c

- The only outlets at the property are toilets and wash hand basins with no showers present on site.

http://www.hse.gov.uk/legionnaires/legionella-landlords-responsibilities.htm

What is meant by the term water system?

A water system includes all plant and equipment for example all the pipework, pumps, cold water storage tanks, valves, showers, water softeners, chillers, heat exchangers, cooling towers, calorifiers, little used outlets and dead legs, humidifiers, air washes, car washes, indoor fountains and water features.

How do I choose a water hygiene company?

Choosing a water hygiene company with the knowledge and skills to manage and control the risk of legionnaires’ disease at your site is made easier with the help of the Legionella Control Association. The LCA hold a register of members who have met their requirements on an annual basis and have passed their annual audit of systems.

A key factor should be the training of site staff to carry out water hygiene work competently. A provider will be able to demonstrate how their employees are trained and audited to ensure continual compliance with current standards.

The LCA code of conduct sets out the standard of service a client should expect from a water hygiene provider. The code requires a Service Provider to set up an appropriate management system for the control of legionella complying with the latest HSE guidance for the control of legionella bacteria.

How many cases of Legionnaires Disease were there last year?

The figures from 2021 – 2022 are not available yet however between 1st January – 31st October 2020 according to a report by Public Health England, there were 254 cases of Legionellosis cases reported in England and Wales.

The figures from 2021 – 2022 are not available yet however between 1st January – 31st October 2020 according to a report by Public Health England, there were 254 cases of Legionellosis cases reported in England and Wales.

https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/948028/Legionella_Mthly_Rprt-Aggregate_rprt_Jan-Oct20.pdf

If you have any questions in regards to Legionella control FAQs or any other questions, please do not hesitate to call us on 01454 417 920

Follow us on

Everyone is potentially susceptible to infection, but some people are at a higher risk e.g. those over 45 years of age, smokers and heavy drinkers, those suffering from chronic respiratory or kidney disease, and people whose immune system is impaired. Symptoms of Legionnaires’ disease may include fever, chills, headache, muscle aches, and tiredness.

Everyone is potentially susceptible to infection, but some people are at a higher risk e.g. those over 45 years of age, smokers and heavy drinkers, those suffering from chronic respiratory or kidney disease, and people whose immune system is impaired. Symptoms of Legionnaires’ disease may include fever, chills, headache, muscle aches, and tiredness. Legionella bacteria (legionella pneumophila) are common in natural water courses such as rivers and ponds. Since legionella is widespread in the environment, they may contaminate and grow in man-made water systems such as cooling towers and hot and cold-water services. Spa baths, Jacuzzi’s and hot tubs also provide a potential breeding ground for legionella bacteria as they provide optimum conditions for the bacteria to grow and multiply to sufficient numbers for a system to be colonised.

Legionella bacteria (legionella pneumophila) are common in natural water courses such as rivers and ponds. Since legionella is widespread in the environment, they may contaminate and grow in man-made water systems such as cooling towers and hot and cold-water services. Spa baths, Jacuzzi’s and hot tubs also provide a potential breeding ground for legionella bacteria as they provide optimum conditions for the bacteria to grow and multiply to sufficient numbers for a system to be colonised.

The figures from 2021 – 2022 are not available yet however between 1st January – 31st October 2020 according to a report by Public Health England, there were 254 cases of Legionellosis cases reported in England and Wales.

The figures from 2021 – 2022 are not available yet however between 1st January – 31st October 2020 according to a report by Public Health England, there were 254 cases of Legionellosis cases reported in England and Wales.